ThermoWorks Billows Temperature Control Fan

Smoking-Meat.com is supported by its readers. We may earn an affiliate commission at no extra cost to you if you buy through a link on this page.

Read this article without ads

The Signals thermometer is a great product all by itself with (4) probes, Wi-Fi and bluetooth capability, and so much more. ThermoWorks has now released their new temperature controller fan which works with the Signals, turning the thermometer into a temperature controller.

The temperature control fan is called “Billows” and with 46cfm, it is well suited for the Weber Smoky Mountain smokers, Kamado cookers such as the BGE, barrel smokers such as the Pit Barrel Cooker, and any other cookers that have similar intake vents.

The billows simply connects to your Signals thermometer via a USB-C cable and once you set the pit temperature, it will seek to maintain that by turning the fan on and off as needed to blow air onto the coals.

The Fan Unit

The fan is able to move 46cfm (cubic feet per minute) and is made of some sort of heavy duty molded plastic which is cool to the touch and able to handle high temperatures without melting.

Comes with a soft, compressible gasket on the mouth of the fan and a easy-to-use clip ready to mount to many different types of smoker vents with ease.

Fan is weatherproof and is designed with the fan intake and USB-C connection on the bottom so no water gets into the fan if it stars raining during use.

USB-C to USB-C cable

This is a common, easy to find cable so if you ever need a replacement, it's easy to get.

This cable connects the fan to the fan adapter.

Fan Adapter

Plugs into Signals on one end and the other end contains (2) connections. One is for the USB-C cable to the fan. The other is for the power supply.

Flu Tape

Billows comes with a 4 to 5 inch piece of metallic, heat resistant flu tape so you can seal up any open areas around the fan to prevent air leaks.

If you need more tape, it is readily available at most hardware stores.

My first test was performed on my 22-inch Weber Smoky Mountain smoker.

Here's the bottom intake vent that I've decided to use (this smoker has (3) of these vents around the bottom of the smoker.

I attached the Billows fan unit to the lower left hole as that seemed to give me the best angle for the airflow into the charcoal area.

To attach, simply pinch the two ends of the clip together and push it through the hole. Once inside, release the clip and it holds the fan in place securely.

Here's what it looks like from the inside of the vent:

Now, just use the flu tape to cover the other holes.

Like so–

Note: Be sure to remove the yellow plug from the bottom of the fan before use

Plug the long USB-C cable into the connection on the bottom of the fan. You may find it easier to do this before installing the fan.

Plug the fan adapter into the USB-C connection on Signals

Connect the long USB-C cable to the “Fan” side of the adapter and then plug the Signals power adapter into the “Power” side of the fan adapter.

Once you plug the Signals power adapter into a power outlet, the fan should immediately begin running.

Here's the overall setup:

Plug the ambient pit probe included with Signals into channel 4. This is the channel that Billows uses to control the temperature.

Clip the pit probe onto the food grate using the clip provided with your Signals or you can use a small potato to hold it slightly above the grate.

For the Weber Smoky Mountain, I recommend filling the charcoal ring with dry, unlit lump charcoal then pour about ½ to ¾ chimney of lit charcoal on top.

Here's some instructions for using the charcoal chimney if you are not familiar with it.

Place the lid on the smoker, set the exhaust vent at ¼ to ½ open and let it preheat for 30 minutes or so to come up to temperature and stabilize.

For my test, I placed a smaller amount of unlit charcoal and about ½ chimney of lit charcoal.

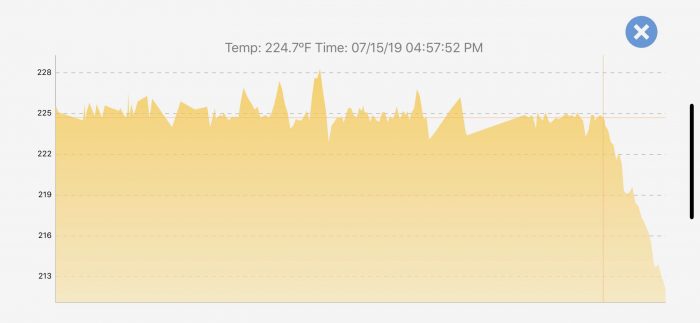

With my configuration, Billows held 225°F within just a degree or two for around 3.5 hours. With more unlit charcoal, it would be able to maintain this temperature for much longer.

Here's a graph to show the progress.. beginning at 1:38 PM to around 5 PM where it started dropping off.

I did not see anything during my initial test that annoyed me or that I felt like was designed badly or did not function as it could. As I continue to use it, we'll see how it goes.

Based on my research, certain plates and/or adapters will make it easier to connect to some smokers/cookers and hopefully these will be included in future purchases or very inexpensive to add on when you purchase the Billows for your particular smoker. According to ThermoWorks, some adapters will be available in early August.

For my particular smoker, it connected perfectly, worked exactly as advertised and I was able to do it without any complications so I have to give it major kudos for a very well designed tool.

As you already know, I only recommend products that I love and enjoy using.

Just to clarify a few things:

- Billows ONLY works with Signals by ThermoWorks.

- Signals must be plugged into power for Billows to work

If you do not have the Signals multi-probe thermometer, you can purchase it HERE.

If you have Signals and would like to purchase a Billows or check it out further, CLICK HERE.

Let me know in the comments below if you have further questions about this.

Jeff,

Any chance you have tips or guidance for DIYer building an UDS for the first time specifically with the billows in mind? Rather than putting in an airflow and rigging the billows to fit, I’d like to build in the slot specifically for the billows. Any how tos or tutorials you have in mind?

I have been trying to get Billows to work for multiple tries. Here it is on a 91° day and I can’t get billows to get my heat above 230° while I’ve set it up to run at 275°. About 15 minutes ago I gave up, turned off Billows, opened the vents, and now am running at 260°. This is over almost 6 hours of cooking!

Mind you, I do like Signals. It does connect to my phone which “Smoke” never did.

IF you can get your temp to the desired flame heat, Signals does keep it very even. But, if you do not, or cannot get to your desired heat, Billows is worthless.

Gary, I recommend you contact Thermoworks and see if they can figure out what is causing the problem.. I use mine very successfully on a WSM in any temperature and the airflow is plenty to stoke the coals and get the heat to where it needs to be.

What smoker are you using this on?

I have a Grillpro charcoal smoker with no dedicated vents on the bottom. Just a half inch or so gap between the inner edge of the smoker and the pan for the charcoal. Is there a hack to plugging the half inch gap? This way I can drill through the outside of the smoker for the billows?

what did you do with the other two vents on the bottom? fully closed? partially open? adjusted during test?

All bottom vents closed fully so it would only get air from the billows.

Jeff, I read this review with interest. It seems logical that the fan would add temperature when it comes on, but is there any way it can be used to reduce temp that has gotten too high? I am thinking of my Pit Barrel Cooker, which I have no problem at all getting hot, but keeping it below 275 degrees is difficult here in the summer heat and humidity of Alabama, approximately 670 feet above sea level here in Birmingham. Have you tested this with your PPC? Whether yes or no, I would appreciate any thoughts you might have. I love your recipes and sauces!

Tom

I have not tested the Billows with my PBC yet but I have that on my list of things to get done soon. As far as fans go, they do blow on the coals to increase the heat but they do not have the ability to lower the temperature in any way. The PBC does tend to run hotter than many other smokers but you can often adjust this some by decreasing the amount of lit charcoal that you start with. They recommend 40 pieces of charcoal to start but what would happen if you started with say 25 pieces? I have not tested as low as 25 pieces but we do know that each piece of coal gives off x amount of heat so for every piece you add or don’t add, the heat should increase or decrease by that much.

Did you ever get to play with this and the PBC?

Doug,

It works great.. use the special adapter they make for the Kamado and use less charcoal than you normally would. You should be able to hold temps down around 250 or even less if you want to.

You can find the Mounting Plates at https://www.thermoworks.com/TX-1607X-M1

Here is a photo of Billows attached to a Pit Barrel Cooker using a Kamado Mounting Plate.

As I understand it, this new BILLOWS gismo works with SIGNALS only ThermoWorks in their immense financial wisdom decided to forget about the customers who already had bought their SMOKE unit. With little engineering work, they could have made the BILLOWS work with their SMOKE units as well. I am not about to throw away the expensive SMOKE unit and spend more money on their more expensive SIGNALS unit. Forget ThermoWorks ! ! !

That bellows is great, but I use an old hair dryer on the vent of my 18 inch Weber Smokey Mountain smoker and it works when needed. Just an idea.

The bellows is controlled by a computer so it goes on and off as needed to maintain a very precise temperature so some might find that to be easier but as I’ve always said, “If it’s not broke, don’t fix it”.

If an old hair dryer works for you then I see no reason to change it up ;-)

I purchased a barrel smoker a few months back and have been putting it through its paces since. Two weeks ago, I encountered my first cook with absolutely nary a breath of wind. I mean dead still with ambient air temperature in the mid 90s and humidity hovering above 85%. I quickly noticed that the smoker was unable to stay at a chosen temp for long, a characteristic that, previously, was one of the best things about the barrel. I can isolate a chosen temp and maintain it for hours on end by making only occasional tweaks of the vents, top or bottom. But, without any wind at all, that just didn’t work. That made sense to my elementary understanding of thermodynamics.

I grabbed a small, tabletop fan and set it on the ground pointed toward one of the bottom vents. It didn’t work, so I tried different angles and distances from the barrel but couldn’t get it to make a controllable difference.

So I moved it to the top of the barrel and turned the back of the fan toward that vent – actually several holes – to try and suck air through those rather than force air into the bottom. That worked much better. I was able to isolate and hold the temp at 235 until the fuel got low and, even then, increasing fan speed helped keep the temp close until the fuel was completely spent.

So, I wonder: might it be better to suck air through the top than to force it in at the bottom? My experiment seems to so suggest.

I’ll continue this work and keep you posted.

Very interesting indeed.. keep us posted for sure!